Special Automotive Tooling from LMT Tools

Special Automotive Tooling from LMT Tools

During the machining of workpieces most processes are performed using standard tools that are most versatile in use. Solid carbide millers and drills, reversible plate tools, tap drills with standardized dimensions or standard reamers fill the tool cabinets of industry. ISO hard metal qualities with high performance coatings characterize the state of today's standard production technology. Often the tool manufacturers additionally modify the position of the cutting blades or the cutting geometry, for example by rounding, to increase the material removal rates or the resulting workpiece quality in specific applications. This produces special effects that are, however, still within the known standard framework.

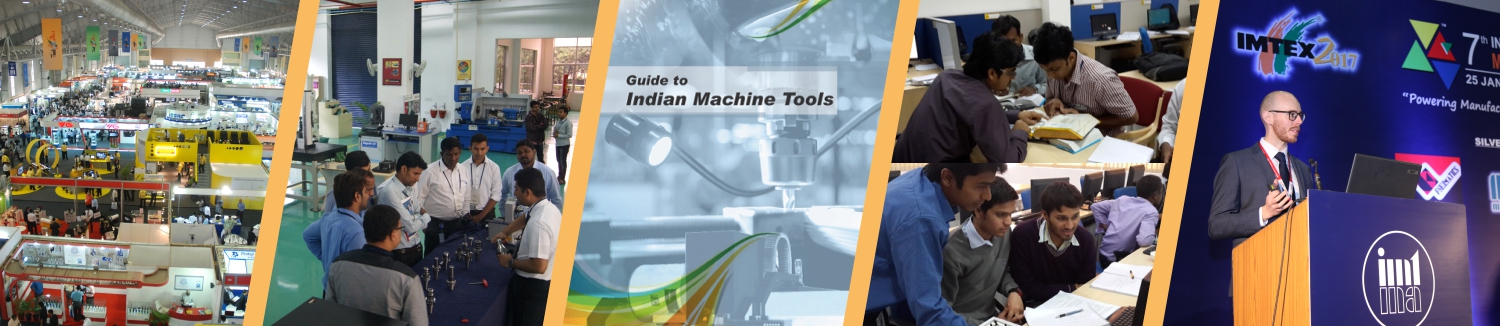

Special tool for the reverse finishing of a diameter (source: LMT Group)

Special tool for the reverse finishing of a diameter (source: LMT Group)However, there are also tool designs that are uncommon and therefore mostly unknown. These are special tools designed for the finishing of a very specific workpiece to not only marginally, but significantly increase the efficiency of production. The design of such tool systems is highly complicated and requires great engineering know-how. Often it is difficult even for an expert who does not deal with such solutions daily to recognize what the tool is actually good for

The article below is to show examples from the comprehensive product range of LMT Tools Group for very specific tool systems characterized by a particular design and having been customized for the user, in line with the Corporate Claim of LMT exactly yours.

Actuator technology for highest precision

Highest precision in large quantity is also required in the automotive industry. For example, in the finishing of crankshaft bearing bores extremes are encountered. Efficiency, smooth running and low-wear operation of the engine depend on the quality and dimensional accuracy of this central drilling process. Its high-precision finishing is therefore done using line boring bars, whose design, holder systems and cutting plates must be individually designed and adapted for each engine type.

Compensatable line bore bar for the fine finishing of bores (source: LMT Group)

In a use case the pre-finishing of the additional bevels of the bearing bridges of different widths has already been integrated. Thus the customer could significantly increase the tool life by using the new line bore bar with compensation: During pre-finishing by 50 per cent and during finishing even by 100 per cent compared to the standard methods. At the same time the cycle times could be reduced by up to 70 per cent.

Multifunctionality increases productivity

Especially in large series production multifunctional tool systems are an important condition for an increase in economy. This also includes the finishing of turbochargers. They consist of highly heat resistant materials, for example cast steel 1.4837 and 1.4848, and place extreme demands on the cutting material, cutting geometry, cutting edge preparation and coating. This in turn makes them to one of the most costly automotive parts to produce.

Multifunctional tool system for reaming, face and circular milling (source: LMT Group)

Multifunctional tool system for reaming, face and circular milling (source: LMT Group)Using a special combination tool from LMT Kieninger the various finishing methods of reaming, face and circular milling are performed multifunctional by a single tool. The costly tool change is obsolete and with it a potential error source. This reduces process times and increases process reliability.

In another example housings of an electropneumatic impact hammer from the material AlSi9Cu3 are machined. To date two different tools were used for the work steps drilling/reaming and countersinking. With the PCD-equipped bell tool from LMT Kieninger (figure 4) both steps could now be performed multifunctional by a single tool system. This reduced the processing time from previously 27 minutes to 11 minutes. The high machinery costs alone were thereby reduced by 59 per cent.

PCD-equipped bell tool for drilling/reaming and countersinking (source: LMT Group)

PCD-equipped bell tool for drilling/reaming and countersinking (source: LMT Group)Lightweight design generates special tools

Amongst the future-trends are also ecological aspects, such as weight saving and saving the environment and resources. Here, lightweight materials, such as plastics and plastic composites gain increasingly in importance. The reliable and high performance machining of these materials has become a major challenge for tool manufacturers. Many plastics are highly abrasive, fibrous and temperature-sensitive and differ greatly from metal in their machining properties.

In two examples for the finishing of honeycomb and composite materials special tool solutions from LMT Onsrud (USA) are to be presented.

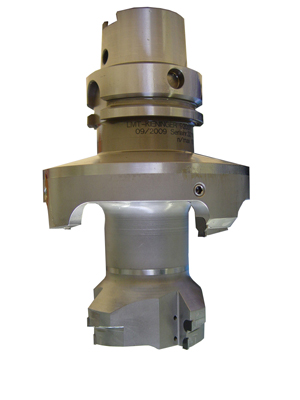

Example of honeycomb lightweight material (source: LMT Group)

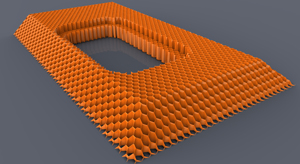

Example of honeycomb lightweight material (source: LMT Group) Special milling cutter for honeycomb lightweight material (source: LMT Group)

Special milling cutter for honeycomb lightweight material (source: LMT Group)Honeycomb is a lightweight material with a honeycomb structure having a high pressure resistance. In combination with thin cover layers from plastic or aluminum it is, for example, used for the fitted cabinets in aircraft. To manufacture edges or milled grooves in this material the so-called honeycomb hoggers are used. Their cutting blades consist of high-seed steel and are zigzag shaped. Generally the cutting geometry is of a design that prevents fraying at the workpiece. The cutting element is hollow and thus lightweight itself. In the front area a thin circular blade from hard metal can additionally be fitted to create a defined cutting area. These tools are used in the speed range of approx. 15.000 min-1.

Another mill cutter from solid carbide for the edge and slot finishing of composite materials, such as CRP, used increasingly in the automotive and aerospace industries, is also of interest. Small alternating milling teeth with positive angles of attach prevent the feared delamination of the material layers and create excellent surfaces. A special face geometry permits the trouble-free engagement with the plastic. These tools can be manually guided or used on CNC machines.

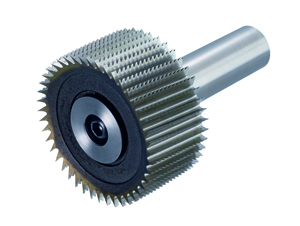

Special solid carbide milling cutter for the finishing of composites (source: LMT Group)

Special solid carbide milling cutter for the finishing of composites (source: LMT Group)

They are available in 2 coating variants: AlTiN and CVD diamond coating. The diamond coating permits especially high cutting speeds on CNC machines and increases the tool life by a factor of 10.

LMT India Pvt Ltd

A40/1, Phase1, MIDC Chakan, Village Nighoje, Tal Khed, Pune 410 501

Ph: 02135 614900

www.lmt-tools.com

marketing@lmt-tools.co.in

© IMTMA 2024. All rights reserved